The maritime industry, a cornerstone of global trade and economy, is facing increasing pressure to reduce its carbon footprint. With international regulations tightening and the need for sustainable alternatives growing, ammonia (N###) is emerging as a promising green fuel. This article explores the potential of ammonia to revolutionize the maritime sector, addressing both its advantages and challenges.

The Urgent Need for Greener Maritime Solutions

Environmental Impact of Maritime Transport

Maritime transport is responsible for approximately 3% of global carbon dioxide (CO2) emissions. As the industry seeks to comply with the International Maritime Organization’s (IMO) stringent environmental regulations and greenhouse gas (GHG) reduction targets set for 2050, the search for viable green fuel alternatives has intensified. The continued reliance on traditional fossil fuels not only contributes to environmental degradation but also threatens the sustainability of the industry. As a result, the focus on identifying carbon-neutral fuel sources has become a priority for stakeholders across the globe.

In addition to environmental regulations, there is an increasing awareness among consumers and companies regarding their carbon footprints. This awareness is driving demand for cleaner, more sustainable shipping practices. The adoption of greener fuels such as ammonia will not only help companies meet regulatory requirements but also cater to the growing market for environmentally responsible products and services. By proactively investing in sustainable solutions, the maritime industry can mitigate its environmental impact and secure its relevance in the evolving global economy.

Pressures and Motivations for Change

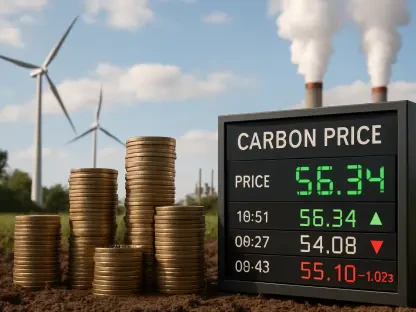

The dual pressures of adhering to environmental standards and reducing GHG emissions are driving the marine industry to adopt new technologies and operational practices. Among the various solutions, ammonia stands out due to its potential to quickly enter the global market and facilitate the sector’s shift towards sustainability. Transitioning to alternative fuels like ammonia also has economic implications, as companies can potentially save on future carbon taxes and benefit from incentives for adopting green technologies.

Furthermore, investments in research and development for ammonia as a marine fuel are picking up pace. Numerous pilot projects and collaborations between industry leaders and research institutions are underway, aiming to address the technical and logistical challenges associated with ammonia fuel use. These collective efforts underscore the growing recognition of ammonia as a viable green fuel that could significantly lower the maritime industry’s GHG emissions. By focusing on ammonia, the industry can leverage existing infrastructure and knowledge, thus expediting the transition towards a more sustainable future.

Ammonia: A Viable Marine Fuel

Production and Availability

Ammonia is a well-known commodity in the maritime industry, primarily transported in gas carriers for use as fertilizer. Its large-scale production via the Haber-Bosch process, which combines gaseous hydrogen and nitrogen (N2+3##=>2N###) with a metal catalyst, makes it an accessible fuel option. This production method is well-established and widely practiced, ensuring a stable and scalable supply of ammonia for various industrial applications, including its potential use as a marine fuel.

The integration of renewable energy sources into ammonia production processes is also being explored, further enhancing its appeal as a green fuel. By using renewable electricity to produce hydrogen through electrolysis, a completely carbon-free ammonia can be synthesized. This green ammonia can then be used to power ships, providing a sustainable loop of energy production and consumption. The adaptation of existing ammonia production facilities to incorporate renewable energy sources represents a tangible step towards reducing the maritime industry’s carbon footprint.

Carbon-Free Status and Abundance

One of ammonia’s most significant advantages is its carbon-free status when produced renewably, allowing ships to eliminate CO2 emissions. Additionally, ammonia benefits from widespread availability, with atmospheric nitrogen (N2) being abundantly and freely available. This abundance ensures that ammonia can be produced in large quantities without depleting natural resources or harming the environment. The versatile nature of ammonia also allows it to be utilized in various forms, such as in internal combustion engines and fuel cells, further broadening its applicability as a green fuel.

Ammonia’s ease of storage and transportation is another pivotal factor in its favor. Unlike hydrogen, which requires complex and costly infrastructure for its safe storage and handling, ammonia can be stored and transported more easily due to its higher boiling point and lower compression requirements. These practical advantages position ammonia as a more feasible solution for widespread adoption in the maritime industry. By leveraging existing supply chains and storage facilities, the transition to ammonia can be more seamless and cost-effective compared to other alternative fuels.

Practical Considerations for Ammonia Use

Storage and Transportation

Ammonia can be transported and stored on vessels more easily than other alternative fuels. It becomes a liquid at -33°C under atmospheric pressure or when pressurized to 8.6 bar at ambient temperature, making it more manageable compared to hydrogen, which requires much higher compression or extremely low temperatures for storage. This practicality extends to the conversion of existing ships to run on ammonia, as the storage infrastructure and handling processes are simpler and more cost-effective.

Additionally, the logistics of bunkering ammonia are relatively straightforward, given its widespread use in various industries. Ports and fueling stations already equipped to handle ammonia could be repurposed to serve ships, streamlining the adoption process. The ability to use existing infrastructure reduces the initial investment required for transition, making ammonia an attractive option for shipping companies seeking to decrease their environmental impact. This ease of integration supports the possibility of rapid scaling, helping the industry to meet its ambitious 2050 GHG reduction targets.

Comparison with Hydrogen

Despite hydrogen’s promising fuel potential, its storage requirements make it less practical for marine use. Ammonia, with its higher volumetric energy density and more manageable boiling temperature, requires considerably less storage volume than petroleum-based fuels, offering a significant advantage over hydrogen. The energy density of ammonia ensures that ships can carry enough fuel for long voyages, reducing the frequency of refueling stops and enhancing operational efficiency.

In contrast, hydrogen’s need for high-pressure tanks or cryogenic storage increases both the complexity and cost of its use in maritime settings. Moreover, the energy-intensive processes required for hydrogen liquefaction add to its overall carbon footprint, detracting from its potential as a truly green fuel. Ammonia’s superior storage characteristics and energy density, combined with its lower operational risks, make it a more pragmatic choice for ships looking to minimize their emissions without compromising on performance. This comparative advantage underscores ammonia’s potential to play a key role in the industry’s push towards a sustainable future.

Challenges and Safety Concerns

Toxicity and Corrosiveness

Ammonia is highly toxic to both humans and aquatic life, posing severe health risks if inhaled at high dosages. It is also highly corrosive, reacting with moisture to deteriorate metals like copper, brass, zinc, and various alloys. The materials selection for ammonia bunkering, containment, and supply systems must account for possible corrosion cracking. Addressing these concerns requires rigorous safety protocols and specialized equipment to prevent leaks and manage accidental exposures.

Developing robust standards for ammonia storage and handling will be essential in mitigating these risks. Training crew members on proper safety procedures and emergency response will be crucial for ensuring safe operations. The industry must invest in comprehensive safety measures and technologies to address the handling risks associated with ammonia. These measures would need to include advanced monitoring systems, regular maintenance schedules, and safety training programs to ensure that all personnel are well-versed in managing ammonia safely.

Combustion and Emissions

Ammonia’s ‘hard ignition’ trait requires a substantial amount of energy from a pilot fuel or another ignition source to combust effectively. Additionally, while ammonia does not produce CO2, its combustion can result in nitrous oxide (N2O), a greenhouse gas with a global warming potential 270 times greater than CO2. Ammonia-burning internal combustion (IC) engines will likely need additional catalytic systems to control N2O emissions. These catalytic systems must be optimized to effectively convert N2O into less harmful byproducts, minimizing its environmental impact.

Ongoing research into ammonia combustion technologies aims to address these challenges. Innovations in engine design and emission control systems are being pursued to make ammonia a safer and more efficient marine fuel. Collaborative efforts between engine manufacturers and environmental researchers are critical in overcoming these hurdles. Through continuous improvement and technological advancements, the marine industry can harness ammonia’s potential while managing its associated risks. Adopting best practices from other sectors that use ammonia extensively will also aid in developing robust solutions for marine applications.

Regulatory and Market Considerations

Safety Regulations

International maritime safety regulations for ammonia fuel handling are still under deliberation at the IMO, potentially delaying its adoption. However, regional initiatives such as the EU’s ‘Fit-for-55’ program show promising progress towards integrating ammonia as a marine fuel. These regulatory frameworks aim to create a consistent set of standards for ammonia use, ensuring that safety protocols are uniformly applied across the industry. Clear and harmonized regulations will foster greater confidence among stakeholders, encouraging investment and adoption in ammonia-fueled vessels.

Engagement with international regulatory bodies will be vital for establishing comprehensive safety guidelines for ammonia fuel. Stakeholders must advocate for the development of clear, enforceable rules covering all aspects of ammonia storage, handling, and usage. Proactive participation in regulatory discussions can help shape the standards to reflect practical considerations. By staying ahead of regulatory developments, the maritime industry can avoid potential compliance issues and position itself as a leader in sustainable fuel adoption.

Market Potential and Future Outlook

The maritime industry, a key player in global trade and economy, is increasingly under pressure to cut down its carbon emissions. This push is intensified by the stricter international regulations and the urgent need for more sustainable energy alternatives. As these pressures mount, ammonia (N###) is emerging as a viable green fuel option. Ammonia presents an attractive solution because it can potentially revolutionize the maritime sector by providing a cleaner and more sustainable fuel source. In this article, we delve into the reasons why ammonia could be a game-changer for maritime operations, examining both its benefits and the challenges that come with its adoption. Not only does ammonia promise to significantly reduce the industry’s carbon footprint, but it also offers an alternative that could align with environmental goals. However, there are hurdles to overcome, including safety concerns, infrastructure upgrades, and economic considerations. By addressing these issues, the maritime industry can move toward a more sustainable future.