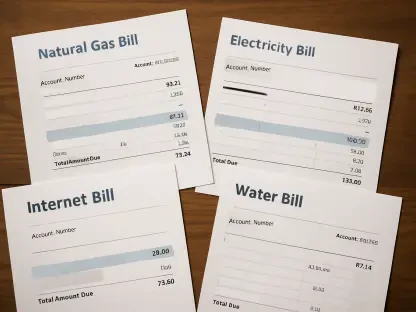

The successful transition to a clean energy economy is being forged not in distant policy debates, but on the factory floors of regional industrial communities across the United States. A fundamental shift in perspective is underway, recasting manufacturing as a form of “civic infrastructure” that is as vital to a community’s health as its schools, streets, and public utilities. This approach recognizes that a resilient industrial base underpins the local tax system, funds essential public services, and provides the stable, skills-based careers that anchor families and neighborhoods. Without a robust and localized manufacturing capacity, the nation’s climate transition risks becoming a supply-chain mirage, failing to deliver on the promise of domestic job creation and economic growth while remaining dependent on foreign imports. The engine for this transformation is the “climate manufacturing ecosystem”—a dynamic local network where industry leaders, technology innovators, a skilled workforce, and community partners collaborate and advance together. Specific regions are already demonstrating how deep industrial know-how and existing supply chains can be retooled to drive America’s next era of industrial prosperity.

The Regional Blueprints for a Clean Industrial Future

New York The Integrated Model

New York stands as the premier model for successfully intertwining a strong industrial history with decisive climate action, demonstrating how the two are not just compatible but mutually reinforcing. Over the last decade, targeted industrial policies, state-led investment from agencies like the New York State Energy Research and Development Authority (NYSERDA), and robust cross-sector partnerships have cemented the idea that industrial and climate goals are synergistic components of a unified economic strategy. This vision is physically manifested in the revitalization of landmark industrial campuses such as the Brooklyn Navy Yard and the Brooklyn Army Terminal, which now house a new generation of climate-tech hardware manufacturers. Furthermore, the city’s 21 Industrial Business Zones (IBZs) serve as a crucial policy tool, protecting these vital manufacturing areas from displacement by intense real estate pressures and ensuring they remain places where innovative ideas are physically built and scaled for the future.

The state’s success is further validated by its vibrant innovation ecosystem, which effectively functions as a “living lab” for new clean technologies. Programs like Futureworks NYC and Scale For ClimateTech have transformed the city’s industrial infrastructure into a launchpad for a new generation of entrepreneurs. The latter initiative has supported over 100 companies, created more than 650 jobs, and helped its participants raise over $1 billion in capital, offering definitive proof of what is possible when infrastructure, policy, and program funding are strategically aligned. To maintain this momentum, future efforts must focus on fulfilling commitments to build new housing without any net loss of industrial space. It is also critical to provide the specialized financing that hardware startups desperately need to transition from prototype to mid-scale production, including more flexible debt options and expanded grant programs with broader eligibility to nurture the next wave of clean-tech innovators.

Pittsburgh and Los Angeles Bridging Potential and Reality

Pittsburgh exemplifies a region effectively leveraging its rich industrial heritage as a launchpad for clean energy innovation, with job growth in the sector outpacing the state average and major investments flowing into new energy projects. The region benefits from powerful anchor institutions like Carnegie Mellon University and major employers such as Westinghouse and Siemens, which provide a steady stream of talent and technological expertise. Despite these significant assets, the region suffers from a critical weakness: a lack of comprehensive ecosystem coordination and the investment required to scale its momentum from promising to dominant. While talent is abundant, Pittsburgh requires a more ambitious, unified push to cultivate and retain top entrepreneurs, systematically connecting them to the necessary support systems, patient capital, and professional networks that can translate immense local promise into national leadership in the climate economy.

Meanwhile, Los Angeles, a former manufacturing powerhouse and a continuing leader in high-tech exports, possesses immense potential fueled by its world-class universities, including UCLA. However, the region faces acute and urgent climate pressures—from severe heat waves and wildfires to poor air quality—that make decarbonization both a moral and an economic imperative. This urgency is compounded by a highly speculative real estate market that has rendered industrial land both scarce and prohibitively expensive. To become a durable climate manufacturing hub, L.A. must pursue a two-pronged strategy. First, it must build upon its existing prototyping spaces to create a coordinated program specifically for manufacturing startups, integrating facilities with curriculum, supply-chain matchmaking, and patient capital. Second, local leaders must convene to develop a “Climate Manufacturing Compact” that aligns the city, county, utilities, labor unions, and investors around shared goals for protecting industrial corridors and setting measurable targets for production space and emissions reductions.

The Great Lakes Forging a Unified Battery Belt

The Great Lakes corridor, stretching from Chicago to Buffalo, has historically served as America’s industrial backbone and is now strategically positioned to become the nation’s “Battery Belt,” leading the production of electric vehicles, semiconductors, and advanced materials. Significant state-level investments in site readiness and infrastructure signal a strong regional commitment to capturing this opportunity. Yet, the region’s primary obstacle is its own fragmentation. A history of “brain drain,” where talent has left for other regions, combined with intense state-versus-state competition for individual projects, has resulted in a fractured landscape. This internal rivalry prevents the region from competing on the global stage as the single, unified manufacturing economy it has the potential to be. Without a cohesive strategy, the corridor risks losing out on generational investments that could secure its long-term economic vitality and leadership in the clean energy transition.

The solution to this fragmentation lies in the adoption of a cohesive regional strategy, complete with a shared playbook and common metrics for job creation, emissions reduction, and domestic content requirements. Such a unified approach would transform counterproductive bidding wars between neighboring states into a collaborative effort to build durable, clean energy industrial growth across the entire corridor. By fostering cross-border partnerships and aligning public, philanthropic, and private capital, the Great Lakes can create a powerful ecosystem that nurtures the entire supply chain, from raw material processing to final assembly. This strategic alignment would not only amplify the region’s collective strengths but also create a more resilient and competitive industrial commons, ensuring that the “Battery Belt” becomes a powerful engine for national renewal and widespread prosperity for decades to come.

From Regional Hubs to a National Commons

The revitalization of American industry and the fight against climate change were revealed to be deeply intertwined projects of national renewal. The departure of industry from communities had historically led to a cascade of negative consequences, including the erosion of the tax base and a diminished capacity to invest in critical public services. The emerging ecosystems in New York, Pittsburgh, Los Angeles, and the Great Lakes offered a powerful blueprint for reversing this decline and building a more prosperous, resilient future. By treating manufacturing as foundational civic infrastructure, these regions demonstrated how to create stable jobs, foster innovation, and address climate challenges simultaneously. Their progress provided a tangible roadmap for other communities looking to harness the clean energy transition as an engine for economic revitalization.

To transform this fragmented progress into a connected national movement, the next step involved building a “Climate Manufacturing Commons”—a collaborative framework where ideas, talent, and production could flow freely across regional borders. Achieving this vision required a concerted effort from government, industry, and investors to co-develop cohesive regional strategies with common metrics and interoperable incentives that fostered collaboration rather than competition. It also demanded sustained investment in climate manufacturing entrepreneurship programs, supported by aligned public and private capital, to nurture the next generation of innovators. Finally, modernizing critical infrastructure, including utilities and rail, while actively protecting essential industrial districts and investing in multi-tenant production spaces, was crucial to supporting startups and small enterprises. Through this integrated, place-based approach, the United States ensured that the clean energy transition became a powerful engine for widespread economic prosperity and community resilience.