In the age of intensified climate change, the steel industry is emerging as a focal point for sustainability transformations, representing nearly 12% of India’s greenhouse gas emissions. The industry, already one of the most significant contributors to the national carbon footprint, is on the brink of a production boom. India, eager to double its steel output by 2030, faces both opportunities and challenges. The real dilemma lies in reducing the industry’s heavy reliance on carbon-intensive methods. This urgency aligns with global initiatives to lower emissions and aligns with the International Energy Agency’s targets for greener practices in steel production. Transitioning to sustainable steel production isn’t just an environmental necessity but a strategic move that could dictate the nation’s economic trajectory in international markets.

Current Trends in Greener Steel Production

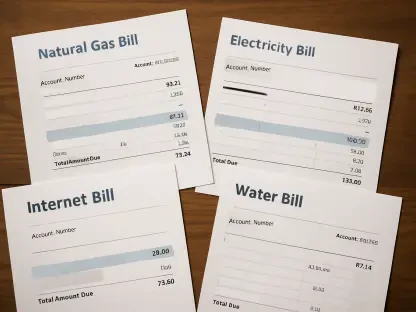

Data and Adoption Statistics

Recent figures indicate that India’s ambitious plans for steel production significantly hamper climate objectives due to its continued use of coal-based technology. In 2030, emissions could snowball if sustainable practices aren’t rapidly enacted. India possesses a relatively young fleet of blast furnaces and ample reserves of low-cost domestic coal, contributing to its reliance on traditional steelmaking paths. However, the transition to greener technologies is gaining pace, with promising data showing a gradual growth toward more sustainable measures. Recent studies highlight this upward trajectory, emphasizing the necessity of accelerating these efforts to meet both national and global greenhouse gas targets.

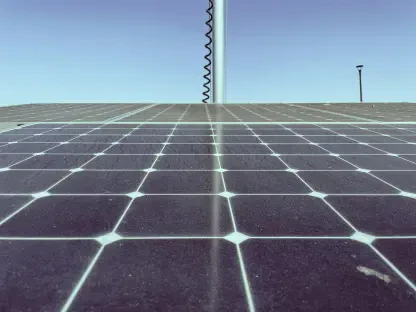

Real-world Applications and Innovations

Several companies and technological innovations are at the forefront of transforming how steel is produced in more sustainable ways. Pioneering organizations are actively exploring and implementing cleaner technologies, including those focusing on hydrogen-based methods or incorporating greater recycling. Case studies have demonstrated successful shifts from traditional emissions-heavy practices to greener production techniques, transforming the industry landscape. Developments such as effective scrap recycling and innovative carbon capture technologies have proven to significantly reduce emissions, ushering in a new era that prioritizes sustainability without compromising production, enhancing the industry rather than hindering its progress.

Expert Opinions and Industry Insights

Industry experts often underscore the imperative nature and inherent challenges of adopting greener practices within the steel production sector. Thought leaders and professionals from across the globe express that cleaner methodologies are crucial for long-term viability and competitiveness. This transformation is not without its complexities, as experts frequently cite the high costs and substantial infrastructure changes needed. However, insights suggest that not adapting could have significant ramifications, resulting in potential market disadvantages, especially with carbon border taxes imminent in key trade regions, such as the European Union. Aligning greener steel production with environmental objectives is pivotal for meeting those ambitious global goals.

Future Prospects for Sustainable Steel Production

Upcoming developments in green steel technologies promise various potential benefits and challenges as these technologies continue to mature. Future innovation holds the potential to unlock unprecedented efficiencies and fulfill decarbonization goals more completely. However, the path forward is complex, requiring cohesive strategies and investments at an unprecedented scale. Predictions signal a profound impact across industries reliant on steel, nurturing an environment where sustainable production is prioritized not just as a legislative requirement but as a forward-looking investment. The implications reverberate throughout the global economy, leading to both promising prospects and forewarnings of competitive shifts for nations and companies alike.

Conclusion and Call to Action

Summarizing the imperative to pivot toward greener steel production methods showcases the balance of opportunity and risk facing the steel industry today. The persistent reliance on emission-heavy methods has considerably challenged India’s position concerning both environmental objectives and competitive market dynamics. As India stands at a crossroads, embracing sustainable methodologies offers a pathway to align production expansion with net-zero commitments set by 2070. Stakeholders are encouraged to prioritize technological upgrades and innovation that foster a more sustainable future, highlighting the importance of strategic alignment to benefit economically while contributing to broader environmental goals.