A Clear Choice: The Consumer Carries the Cost

Faced with persistent trade tariffs and economic uncertainty, U.S. manufacturers have reached a critical decision point—and their verdict is clear. A landmark forecast from the Institute for Supply Management (ISM) reveals that an overwhelming majority are choosing to raise prices rather than undertake the monumental task of reshoring production to American soil. This strategic pivot signals that the intended effect of tariffs—to catalyze a domestic manufacturing renaissance—is falling short of expectations. Instead, the financial burden is being systematically shifted to the end consumer. This article will dissect the data behind this trend, explore the complex factors driving corporate decision-making, and examine the future outlook for an industry navigating a landscape of cautious optimism and lingering headwinds.

The Long Shadow of 2025: A Year of Contraction and Hesitation

To understand the current strategic landscape, one must look back at the turbulent economic climate of 2025. The year was defined by shifting trade policies and widespread uncertainty, which sent a chilling effect across the manufacturing sector. For nine consecutive months, the industry experienced a sustained contraction, compelling many corporate leaders to halt major decisions regarding hiring and capital expenditures. This period of strategic paralysis is now ending. According to industry observers, the “dust is starting to settle” as the Supreme Court’s review of the tariffs’ legality provides a semblance of clarity. This newfound, albeit fragile, stability is prompting companies to finally lock in their strategies for navigating the financial pressures of import duties.

Dissecting the Corporate Playbook: Strategy Over Sentiment

The Path of Least Resistance: Passing Costs to the Consumer

The most prevalent strategy emerging from the ISM data is a direct pass-through of costs. A commanding 74% of manufacturing leaders surveyed plan to increase their sales prices in response to tariffs. This group is further divided, with 32% intending to pass on the entirety of the cost increases, while a larger 42% will employ a hybrid approach of raising prices and absorbing some of the impact into their margins. This decision reflects a pragmatic, short-term solution to protect profitability without the massive capital outlay and operational disruption required for a full supply chain overhaul. For many, adjusting a price tag is far simpler and less risky than relocating a factory.

Reshoring’s Fading Promise: Why Domestic Production Remains a Distant Goal

While tariffs were intended to make domestic production more attractive, the reality on the ground tells a different story. A significant 64% of manufacturers report they have no plans to reshore their operations, citing that it remains more cost-effective to either maintain offshore production or diversify their supply chains to other, less tariff-impacted countries. Only 36% are actively considering a move back to the U.S. This gap highlights the immense practical hurdles of reshoring, which include high capital investment, a shortage of skilled labor, and complex regulatory environments. The data suggests that tariffs alone are an insufficient incentive to overcome these deeply entrenched economic calculations.

Muted Impact of Fiscal Policy: Why Tax Breaks Aren’t Sparking Investment

Further complicating the economic picture is the surprisingly minimal impact of recent fiscal policy. The “One Big Beautiful Bill Act,” which established a favorable 21% corporate tax rate and investment deductions, has failed to ignite a surge in capital spending. A majority of manufacturers (59%) stated the law had no effect on their investment plans, while a concerning 20% are actually reducing expenditures. As industry analysts note, the powerful headwinds of trade disputes and broader economic uncertainty are effectively neutralizing the potential confidence boost from tax incentives. This demonstrates that a stable and predictable policy environment is often more valuable to corporate planners than direct financial inducements.

A Forecast of Cautious Optimism for 2026

Despite the difficulties of 2025, the outlook for 2026 contains a glimmer of “slight optimism.” The ISM forecast projects a 4.4% increase in manufacturing revenues and a modest 3% rise in capital expenditures. This suggests that after a year of contraction and caution, the sector is bracing for a slow but steady recovery. However, this anticipated growth is not expected to be driven by a wave of reshoring. Instead, the prevailing trend will likely be continued supply chain diversification—often called “friend-shoring” or “China plus one”—where companies reduce reliance on a single country without making the full leap back to the U.S. The final verdict from the Supreme Court on tariffs will remain a critical variable, capable of either accelerating this recovery or plunging the sector back into uncertainty.

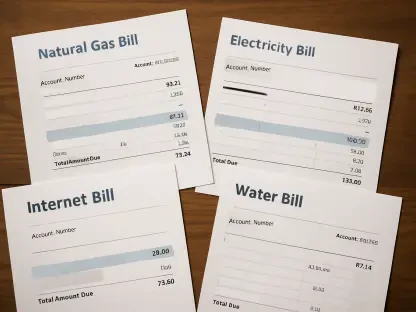

Navigating the New Normal: Key Strategies for Stakeholders

The ISM report offers clear takeaways for all stakeholders. For manufacturers, the path forward requires building resilient, agile, and geographically diverse supply chains that can withstand geopolitical shocks. Pricing strategies must be carefully calibrated to balance margin protection with market competitiveness. For policymakers, the lesson is that tariffs are not a silver bullet for industrial revitalization. To genuinely incentivize reshoring, trade policy must be paired with robust initiatives that address the core challenges of skilled labor shortages, infrastructure deficits, and regulatory burdens. Finally, for consumers, the immediate future will likely involve continued price pressures on a wide range of goods, as the costs of global trade disputes are passed down the line.

The Enduring Calculus of Cost vs. Control

In conclusion, the response of U.S. manufacturers to tariffs reveals a fundamental truth about the modern global economy: pragmatic cost calculations consistently outweigh political sentiment. The decision to raise prices is not a rejection of American manufacturing but a rational business choice in an environment fraught with risk. This trend underscores that the calculus of global production is complex and deeply resistant to change through tariffs alone. As companies continue to adapt to this new normal, their collective decisions will not only determine the prices on store shelves but also define the very structure of the American industrial landscape for years to come.