As the global automotive industry accelerates its transition toward sustainability, the pressure intensifies on every link in the supply chain to innovate and reduce its environmental impact. In a significant move that underscores this industry-wide shift, Maxion Wheels, a premier global manufacturer of automotive wheels, has inaugurated a substantial on-site solar photovoltaic system at its steel wheel production facility in San Luis Potosi, Mexico. This initiative is more than just an operational upgrade; it represents a tangible step in the company’s broader, long-term commitment to decarbonizing its manufacturing processes worldwide. By harnessing solar power directly at the point of consumption, the company is not only advancing its green credentials but also enhancing its energy security and operational efficiency. The project, developed in a strategic partnership, showcases a proactive approach to corporate responsibility, directly addressing the urgent need for cleaner energy sources within the energy-intensive manufacturing sector.

A Strategic Move Towards Decarbonization

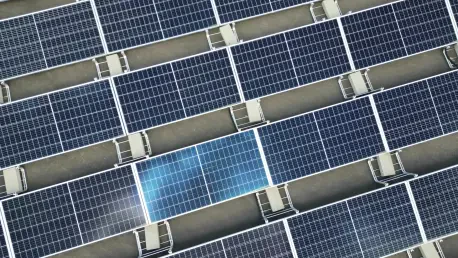

The San Luis Potosi Solar Initiative

The newly commissioned 499 kilowatt (kW) solar array at the San Luis Potosi plant is a testament to the company’s dedication to tangible environmental action. This on-site system is engineered to generate approximately 919 megawatt-hours (MWh) of clean electricity annually, directly powering a portion of the facility’s extensive manufacturing operations. The environmental benefits are substantial, with the project expected to offset an estimated 617 tons of carbon dioxide emissions each year. To put this into perspective, this reduction in greenhouse gases is equivalent to the amount of carbon sequestered by a forest of over 10,200 trees over a ten-year period. Executed in collaboration with energy partner Iberdrola México, the installation leverages advanced photovoltaic technology to maximize energy output and ensure reliability. This direct integration of renewable energy into the plant’s power supply mix marks a critical milestone in reducing the carbon footprint associated with wheel production, a fundamental component of the automotive industry.

This latest solar project is not a standalone venture but a continuation of a well-defined global strategy aimed at embedding sustainability into the core of the company’s operations. The San Luis Potosi installation represents the ninth such solar initiative for Maxion Wheels worldwide, illustrating a consistent and expanding commitment to renewable energy. This development closely follows the launch of a similarly sized 499 kW system at the company’s facility in Chihuahua in 2024, and precedes another planned project in Castaños, which is slated to come online shortly. This deliberate pattern of investment, particularly within Mexico, highlights a focused regional strategy to decarbonize its manufacturing footprint. The consistent model across these locations involves on-site distributed generation, a method that provides a reliable source of clean power to meet a portion of each plant’s significant electricity demands. This approach yields dual benefits: it substantially lowers the environmental impact of production and simultaneously enhances cost stability by reducing reliance on the conventional energy grid.

Expanding The Renewable Energy Footprint in Mexico

The concentration of these renewable energy projects within Mexico underscores the strategic importance of the region to Maxion Wheels’ global operations and its sustainability objectives. As a major hub for automotive manufacturing, Mexico hosts several of the company’s key production facilities, which supply wheels to some of the world’s largest automakers. By investing in solar power at these sites, Maxion Wheels is not only optimizing its own energy consumption but also aligning with the increasingly stringent sustainability requirements of its major clients. The projects in Chihuahua, San Luis Potosi, and the forthcoming one in Castaños collectively form a powerful network of clean energy generation. This regional focus ensures that the benefits of reduced emissions and enhanced energy security are realized in a critical part of the company’s supply chain, contributing significantly to the overall greening of the North American automotive sector and reinforcing its position as a forward-thinking and responsible manufacturing partner.

The adoption of an on-site distributed generation model provides a suite of operational and financial advantages that extend beyond environmental stewardship. For a large-scale industrial operation like a wheel manufacturing plant, energy is a major and often volatile operating expense. By generating a portion of its own electricity, the facility gains a greater degree of insulation from fluctuations in grid energy prices and potential supply disruptions. This increased energy independence leads to more predictable operating costs, a crucial factor in maintaining competitiveness in the global market. Furthermore, the on-site model minimizes transmission losses that occur when electricity is transported over long distances, making it a more efficient use of energy resources. This strategic choice reflects a sophisticated understanding of the modern energy landscape, where resilience, cost control, and sustainability are inextricably linked components of a successful long-term business strategy for any major industrial player.

Aligning with a Global Sustainability Vision

The Roadmap Zero Mandate

These individual solar projects are direct expressions of a much larger and more ambitious corporate vision articulated by Maxion Wheels’ parent company, Iochpe-Maxion. This comprehensive sustainability strategy, known as “Roadmap Zero,” sets a clear and aggressive target for the entire organization: achieving full carbon neutrality across all its global operations by the year 2040. This is not merely an emissions-reduction plan but a holistic framework that re-evaluates the entire product life cycle. Roadmap Zero encompasses initiatives ranging from the responsible sourcing of recycled and green raw materials, like green steel, to continuous improvements in manufacturing energy efficiency. It also drives innovation in product development, focusing on creating lightweight wheels that help reduce vehicle emissions. The strategy is underpinned by concrete, time-bound targets, including a 30% reduction in Scope 1 and 2 CO₂ emissions by 2025 and a 70% reduction by 2030, measured against a 2019 baseline. This demonstrates a structured and accountable approach to achieving its long-term goals.

The commitment to “Roadmap Zero” is further solidified by robust financial and governance mechanisms that integrate sustainability into the company’s core business functions. Iochpe-Maxion has demonstrated its serious intent by linking its environmental performance to its financing strategy, notably through the issuance of US$400 million in sustainability-linked bonds. This financial instrument ties the company’s cost of capital to its ability to meet specific sustainability targets, creating a powerful incentive for progress. Furthermore, the company’s alignment with the principles of the United Nations Global Compact signals its commitment to universal standards of corporate responsibility. A key pillar of this strategy is the ambitious goal to source 90% of all its electricity from renewable sources by 2030. The solar installations in Mexico, therefore, are not isolated environmental projects but are integral, tangible actions that directly contribute to meeting these publicly stated and financially backed corporate objectives.

A Foundation for Continued Progress

The successful commissioning of the solar project in San Luis Potosi, following closely on the heels of the Chihuahua installation, marked a significant advancement in the company’s journey toward its ambitious sustainability goals. These initiatives were tangible proof of the “Roadmap Zero” strategy in action, translating a long-term vision into immediate, measurable impact on the ground. By strategically deploying on-site renewable energy generation at key manufacturing hubs, the company actively reduced its operational carbon footprint and simultaneously fortified its energy resilience. The projects in Mexico served as a powerful model for how industrial-scale manufacturing could be effectively decarbonized, demonstrating a clear path forward that integrated environmental responsibility with sound business practice and set a benchmark for future investments across the company’s global network.