With extensive experience in energy management and grid security, Christopher Hailstone has a unique perspective on the intersection of industrial operations and environmental responsibility. Today, he shares his insights on a significant achievement in sustainable manufacturing: Signature Systems’ recent ISO 14001:2015 certification for its Orlando facility. We’ll explore the practical challenges of meeting this global standard, delve into the company’s circular economy model that transforms used products into new ones, and discuss how such certifications provide tangible value to customers navigating their own environmental, social, and governance (ESG) goals.

The article mentions your Orlando facility earned ISO 14001:2015 certification. Could you walk us through the most challenging aspect of strengthening your environmental standards to meet this global benchmark, and what was the first major change you implemented in the manufacturing process?

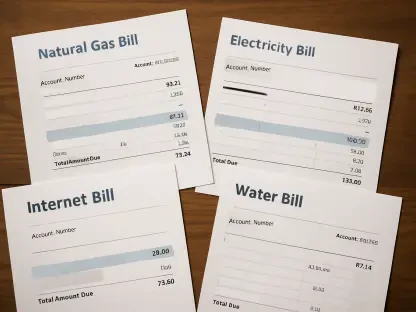

The most demanding aspect wasn’t a single technical fix but rather the cultural shift required to embed a philosophy of measurable environmental control across the entire organization. It’s one thing to have environmentally responsible practices; it’s another to document, measure, and continuously improve them to the rigorous level ISO demands. The first major operational change we implemented was formalizing our waste reduction strategies. We moved from simply using recycled HDPE to creating a meticulous tracking system for every piece of material. This meant quantifying our production waste and treating it not as an inevitable byproduct, but as a valuable resource to be reintegrated. This shift from an informal commitment to a data-driven, accountable process was the foundational step that paved the way for everything else.

You utilize recycled high-density polyethylene (HDPE) in your composite mats. Can you describe the step-by-step process for sourcing this material and share a key metric you use to track the success of your waste reduction strategies during production?

Our sourcing process for recycled HDPE is built on quality and consistency. It begins with identifying and vetting suppliers who can provide a steady stream of post-consumer or post-industrial material that meets our strict engineering specifications. Once a partnership is established, every shipment of recycled material that arrives at our Orlando facility undergoes rigorous testing to ensure its integrity before it’s introduced into our production line. As for tracking success, a key metric for us is what we call our “material circularity rate.” This measures the percentage of recycled HDPE we successfully incorporate into new composite mats versus virgin materials. Our goal is to constantly increase this rate without ever compromising the product durability our customers depend on. Seeing that number climb is the clearest indicator that our strategy is working.

Your end-of-life recycling program is a key part of your circular economy model. How does a customer initiate the process to return used mats, and can you share an anecdote about how this program has directly reduced landfill waste?

We’ve made the process incredibly simple for our customers. When their mats have reached the end of their useful life, they just need to contact our support team. We then coordinate the logistics for the return, ensuring the material comes back to us instead of heading to a landfill. I vividly recall one of our first major returns. It came from a large event application where the mats had endured years of intense use. The thought of all that durable polymer sitting in a landfill was exactly what we wanted to avoid. Instead, we received them back, processed them, and that same recycled HDPE became the foundation for a new set of industrial mats. It was a powerful, tangible moment for the team—seeing our commitment to a circular economy come full circle right there on the factory floor.

Company President Jeff Condino stated this certification reinforces your commitment to environmental responsibility. How does this formal certification help your customers meet their own ESG initiatives, and what has been the initial feedback from them since the announcement?

For our customers, this ISO 14001:2015 certification is far more than just a plaque on the wall; it’s a form of assurance. Many of our clients in the industrial, government, and events sectors have their own ambitious ESG targets. By partnering with a certified supplier like us, they can confidently report that their supply chain adheres to the highest global standards for environmental management. It provides them with the verifiable, third-party documentation they need to prove their projects are built on a foundation of sustainability. The feedback has been overwhelmingly positive. We’ve heard from several customers that this simplifies their procurement process and gives them a clear, competitive advantage when bidding on projects that have stringent environmental requirements.

Do you have any advice for our readers?

My advice is to view sustainability not as a final destination but as a continuous operational discipline. Don’t be intimidated by the idea of a massive, top-down overhaul. Start by identifying one or two key processes where you can make a measurable impact, whether it’s reducing waste, improving energy efficiency, or sourcing recycled materials. Use standards like ISO 14001 not as a burdensome checklist, but as a roadmap to guide your efforts. True, lasting environmental responsibility is achieved when it’s woven into the very fabric of your company culture and daily operations, creating value for your business, your customers, and the planet.