Amid a global push for sustainability and circular economies, the very industry designed to close the loop on plastic waste is facing an unprecedented and prolonged period of economic instability. Far from being a straightforward process of collection and reuse, the North American plastics recycling sector is a complex ecosystem grappling with market forces that threaten its viability. The persistent turbulence experienced over the past year is not an anomaly but a symptom of deep-seated structural challenges that have left many businesses struggling to survive, casting a shadow over the future of circularity.

The Precarious State of a Critical Industry

The North American plastics recycling ecosystem is an intricate supply chain that begins at the curb and ends with a new product on a store shelf. The journey starts with consumers placing plastic containers in recycling bins, after which the materials are transported to Material Recovery Facilities (MRFs). At these facilities, plastics are sorted from other recyclables, baled, and sold to reclaimers. These reclaimers are the industrial heart of the system, cleaning, grinding, and converting the postconsumer material into recycled plastic pellets or flakes that can be sold to manufacturers.

Key players in this chain include not only the MRFs and reclaimers but also the end-market buyers—the brands and product manufacturers who purchase recycled content to incorporate into their packaging and goods. Materials like recycled polyethylene terephthalate (rPET) are foundational to the promise of a circular economy, allowing companies to meet sustainability commitments and reduce their reliance on virgin resources. The health of this entire ecosystem, therefore, depends on a delicate balance of supply, processing capacity, and, most critically, consistent demand from these end markets.

Unpacking the Market Mayhem Key Drivers and Data

A Perfect Storm of Economic Pressures

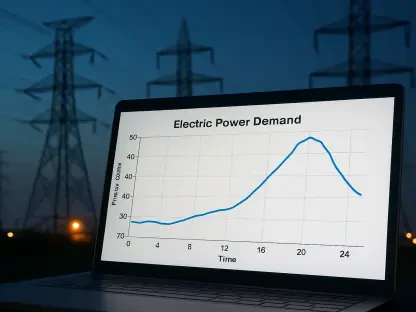

The current turmoil is rooted in a fundamental economic imbalance: an overabundant supply of recycled material is clashing with unexpectedly weak demand. This glut has created a buyer’s market where prices for recycled plastics have been suppressed for a sustained period. This situation is forecasted to continue, with experts anticipating another soft year on the demand side, further straining the financial stability of domestic suppliers.

This pressure is intensified by fierce competition from low-cost virgin plastics. When the price of newly manufactured plastic resin drops, it becomes a more economically attractive option for manufacturers, diminishing the incentive to purchase recycled material. Compounding this challenge is a persistent influx of high-quality, inexpensive recycled plastic imports. Foreign rPET, in particular, often offers superior quality at a price point comparable to domestic material, making it a highly appealing alternative for buyers and further eroding the market for U.S. and Canadian reclaimers.

By the Numbers Declining Rates and Sobering Forecasts

Recent data paints a sobering picture of the industry’s performance under these hostile conditions. The U.S. PET bottle recycling rate saw a notable decrease, falling to 30.2 percent from 32.5 percent the previous year. This decline in collection is mirrored by a drop in demand, with sales of domestic rPET to end markets in the United States and Canada falling by three percent. These figures indicate that less material is entering the system and that the material being processed is struggling to find buyers.

The data on imports is particularly stark. The volume of rPET imported into the U.S. surged to an all-time high, accounting for a staggering 23 percent of the total rPET supply. This flood of foreign material directly contributed to a slight decrease in the average recycled content in U.S.-made PET bottles, which fell to 15.9 percent as cheaper virgin and imported materials displaced domestic supply. While seasonal factors like MRFs destocking inventories at year-end may create temporary price increases, analysts caution against misinterpreting these as signs of a genuine recovery, attributing them instead to short-term supply constraints rather than a strengthening of underlying demand.

Navigating the Headwinds Economic and Operational Hurdles

The crippling market volatility has had tangible and damaging consequences for domestic recyclers. The unpredictable pricing and demand make long-term financial planning nearly impossible, placing many operators in a precarious position. In the past year alone, these severe pressures forced four major rPET recyclers to close their doors, significantly reducing the nation’s capacity to process postconsumer plastics and threatening the resilience of the entire supply chain.

A poignant example of this crisis is the closure of a Phoenix Technologies International facility in Ohio. The plant, which had an annual processing capacity of 140 million pounds of PET, was shut down despite the company having undertaken significant cost-reduction measures and completing a major capacity upgrade only a year prior. This case illustrates how even established, innovative companies are being overwhelmed by market forces beyond their control.

This downturn creates a frustrating paradox for the industry. While market conditions have worsened, the operational side of recycling has shown marked improvement. The total volume of postconsumer PET bottles sent to reclaimers has increased, and the overall efficiency of the reclamation process has improved, with the yield of usable material rising from 81.5 percent to 85.2 percent. These gains demonstrate that the industry is becoming more effective at its core function, yet these efficiencies are not enough to overcome the hostile economic environment.

The Policy Puzzle How Trade and Tariffs Fuel Uncertainty

Adding to the economic strain is a layer of policy-driven uncertainty, particularly concerning U.S. trade regulations and tariffs. Inconsistent and abruptly changing trade policies have served to further destabilize an already fragile market, leaving stakeholders unable to plan effectively. This volatility has been described by industry experts as “the cherry on top” of a struggling market, creating cascading impacts that have exacerbated the downturn.

The challenge for businesses has been the whiplash of regulatory changes. For instance, the initial exemption of virgin and recycled PET from a broad tariff regimen, followed by a sudden reversal, created a chaotic environment where long-term sourcing and sales strategies became untenable. When businesses cannot forecast costs and market access beyond the immediate month, investment stalls and risk becomes unmanageable, chilling growth and threatening existing operations. This lack of a stable regulatory landscape undermines the competitiveness of domestic recyclers who must contend not only with market economics but also with unpredictable government actions.

Forging a Path Forward Resilience and Future Prospects

Despite the grim market overview, there are positive developments that signal the industry’s underlying resilience. One of the most encouraging trends is the significant growth in the recovery of non-bottle packaging, particularly PET thermoforms like clamshell containers. The collection and processing of this material surged by an impressive 52 percent, demonstrating that the recycling system is capable of adapting and expanding to capture a wider range of plastic packaging.

This progress, coupled with the aforementioned gains in system-wide efficiency, suggests a strong potential for strengthening the domestic supply chain. With strategic investment in infrastructure and innovation, the industry can build upon these successes. Expanding the capacity to process all types of PET packaging, not just bottles, is a critical step toward creating a more robust and diversified feedstock supply, which could help insulate the industry from some market shocks.

Looking ahead, these areas of expansion represent the most promising avenues for future growth. The ability to successfully recover and create end markets for a broader array of plastic formats, like thermoforms, could be a key disruptor that reshapes the industry. However, realizing this potential is entirely dependent on cultivating the stable, long-term demand needed to justify the necessary investments in collection, sorting, and processing technologies.

The Verdict A Call for Systemic Change to Save the Cycle

The sustained turbulence in the plastics recycling market is not the result of a single issue but a convergence of powerful, interconnected forces. An oversupplied market, intense price competition from virgin and imported materials, and unpredictable trade policies have created a perfect storm that threatens the foundation of the circular economy for plastics.

This crisis underscores a fundamental truth: operational efficiencies and collection improvements alone cannot save the system. The critical missing piece is the presence of stable, reliable, and economically viable end markets for recycled materials. Without consistent demand to pull material through the supply chain, the entire cycle breaks down, regardless of how effectively materials are collected and processed.

Ensuring the long-term health of plastics recycling requires a shift toward systemic support. This includes implementing policies that stimulate domestic demand, such as recycled content mandates, and fostering a regulatory environment that provides the stability needed for long-term investment. By strengthening domestic infrastructure and cultivating reliable end markets, stakeholders can work to build a more resilient system capable of weathering economic headwinds and fulfilling its essential role in a circular economy.